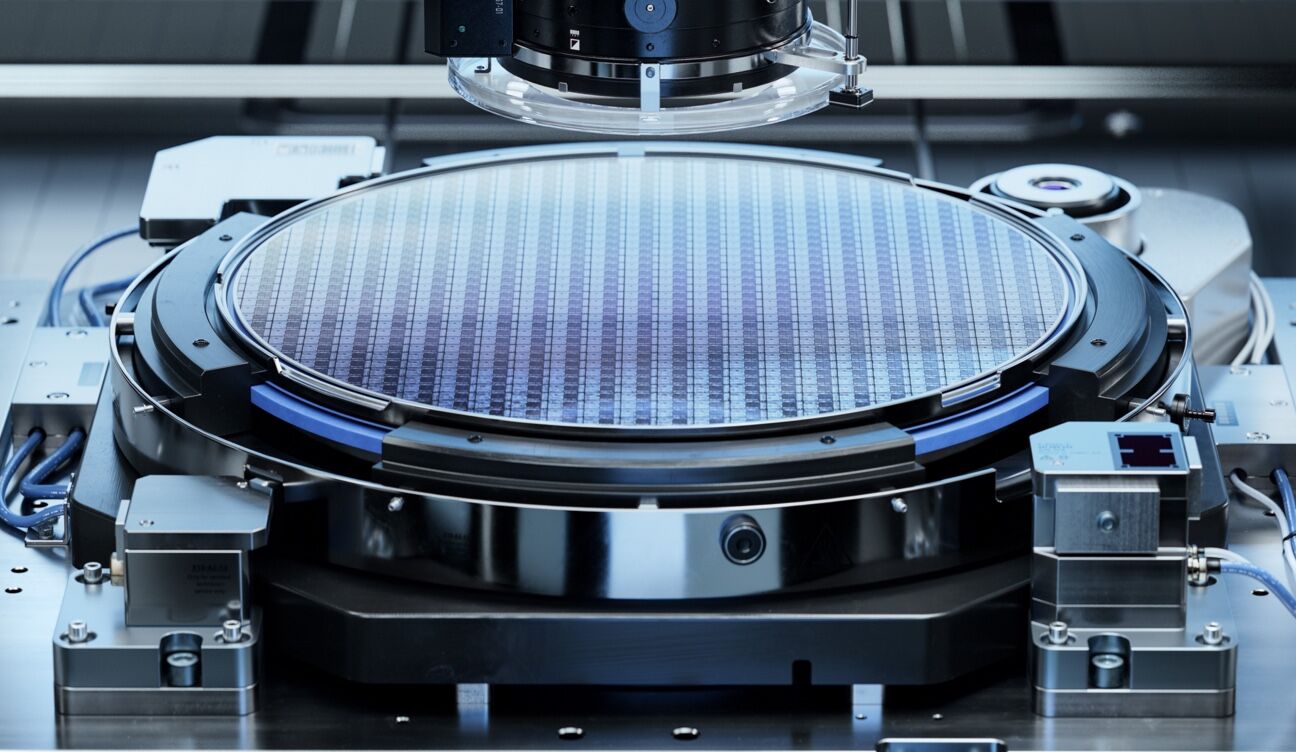

New chip fabrication processes bring exponential complexity to semiconductor design and manufacturing. The entire workflow, from functional logic verification and physical design to optical proximity correction, now relies heavily on HPC and electronic design automation (EDA) tools.

Kunpeng HPC Solution delivers a breakthrough by deeply adapting and optimizing leading China-made EDA tools. This significantly improves simulation efficiency, resulting in shorter design cycles and higher manufacturing quality. It is the reliable, advanced technical foundation for your chip R&D and production.